Frequently Asked Questions

General

- Where is Vexcolt Europe located?

Vexcolt Europe is active worldwide and has offices and manufacturing facilities in:

- Europe

- The Middle East and Africa

- India

- Hong Kong and mainland China

- Singapore

- Who is Vexcolt Europe?

Vexcolt Europe is a full-service consultancy and production company with specialization in expansion joints, fire barriers and control joints. Our consultants will help you to choose the movement solution most suitable for your project. Feel free to contact us for more information.

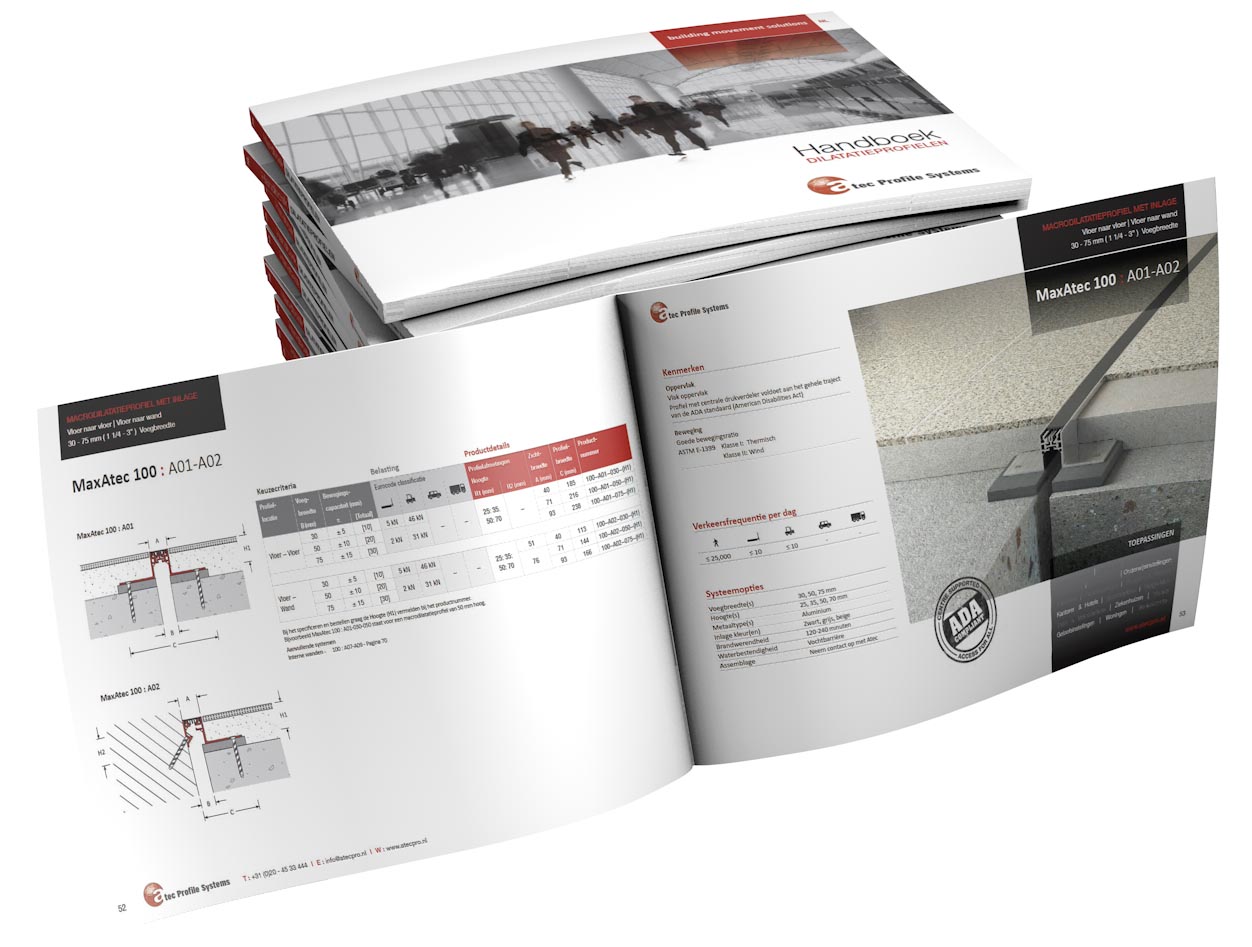

- How do I receive an Vexcolt Europe Handbook?

The Vexcolt Europe handbook is a complete overview of products in the field of expansion joints, fire barriers and control joints with specific advice regarding to the fire protection and waterproofing of expansion joints. This handbook also details systems suitable for seismic zones.

Please request our Handbook by filling in this form.

- How can I order products?

Please contact our specialists via our website or by phone – for UK customers please call: 0370 787 6543. Our technical team will be pleased to help ensure you select the best solution in terms of practicality, aesthetics and value.

- Where can I find pricing information?

The most important point is to determine a project specific solution for you. After that our team will translate that agreed solution into a fully-costed proposal.

- Are the joints suitable for indoor and outdoor use?

We have solutions for both internal and external applications.

- Why are floor joints special?

Jointing systems appear in floors, walls, ceilings and roofs and share many similar characteristics in terms of movement, resistance to fire and waterproofing. Floor joints however, must be able to support loads from a variety of sources including pedestrians, pallet trucks, cherry pickers, scissor lifts, forklift trucks, passenger vehicles and lorries. It is therefore critical to understand the magnitude and frequency of these loads in specifying floor joints.

Technical

- What is an expansion joint?

Expansion joints are gaps that run throughout a structure essentially dividing a building into segments which can move independently of each other. They run through floors, walls, ceilings and roofs and are designed into larger-scale structures to allow those buildings to deflect in response to movement arising from thermal gain and loss, wind loading, drying shrinkage and creep as well as seismic forces.

- What is a control joint?

Control joints are small gaps formed in floors and walls used to accommodate localised deflections in finishes. These small-scale movement arise from creep, drying shrinkage and thermal gain and loss and, if not accommodated can easily damage finishes applied to floors and walls.

- Why use joints?

On one hand we build structures from relatively brittle materials such as concrete and masonry and then apply similarly fragile finishes such as tiles and coatings to the surface. On the other hand, all structures experience movement and that combination of movement allied with brittle elements of construction can result in substantial damage both to the fabric of the structure as well as the finishes zone.

Expansion joints and control joints are used to absorb these movements and to protect both the structure and any finishes applied to it.

- Is every floor suitable for movement joints?

Vexcolt/Atec Profile Systems have developed suitable movement joints for every type of floor application. For floors with hard finishes such as ceramic tiles, we have movement control joints to protect the tile edge and absorb both compressive and tensile movements. For industrial floors we have all-metal joint for heavy loads.

In addition, we have products for fire resistance, water resistance and repair as well solutions for eliminating electrostatic discharges in critical areas.

Our specialists have vast experience in minimizing the impact of movement in complex systems including specialist solutions for projects in seismic zones.

- What are floor bays?

Bays are floor subdivisions separated by control joints. These are small systems installed in floors and walls to allow localized movements that arise from drying shrinkage, thermal gain/loss and creep. By dividing up floors into bays we prevent random cracking.

- Is a sealant suitable as a control joint filler?

Sealant is rarely suitable as a control joint filler, particularly over the long term. Over the short-term sealants are generally cheaper than factory-formed joints but this is a short-lived economy. Typically:

- Sealants have limited longevity typically lasting between 3 and 6 years. This presents the client with an ongoing maintenance problem. Factory formed joints have a life-expectancy of 20 years plus.

- Where brittle finishes such as floors with a concrete finish (or where thin coatings are applied) or floors which are tiled then the sealant won’t prevent damage to the concrete or tile edges. It simply doesn’t offer support to brittle edges as traffic passes over the control joint. Factory-formed joints comprise a metal envelope with a flexible core which both moves to accommodate deflections and protects the edges of finishes from damage in the most aggressive traffic environments.

- Sealants are site applied after finishes have been installed and this places reliance upon:

- Correct site preparation including cleaning and priming of the control gap as well as ensuring that the correct width to depth ratio of sealant is maintained by using backer-rods set at the correct depth.

- Factory-formed control joints are pre-manufactured and simply slotted into place with little site preparation required. No cleaning, no priming, no backer-rods. Just fix and forget.

- The delay in installation of sealants gives a window of opportunity for finishes to be compromised by construction traffic for example.

- Factory-formed control joints are installed as finishes are laid so there is no window of opportunity for finishes to be damaged.

- Certain sealants exude an oil which can stain abutting finishes such as lighter coloured marble and terrazzo.

Factory-formed joints are fully cured within the manufacturing environment and migration of contaminants is simply impossible.

- What is the correct installation procedure of a movement joint?

An installation Method Statement will be included in every delivery of product that you receive. It describes in details the contents of the pack and a step by step guide describing how the profile is installed. We recommend, however, that you use certified personnel to ensure that the joints are correctly installed.

- Waterproofing expansion joints?

As expansion gaps pass through a structure dividing it into segments which can move independently of each other these gaps can provide a route for water to pass from floor to floor. We use a double-layer system where a membrane is bonded to the structure beneath the joint and is cross-linked to the structural waterproofing. In addition, secondary layers of membrane are attached to the sides of the expansion joints entirely encapsulating it within an entirely waterproof envelope.

Please view our products for more information or contact one of our specialists for advice.

- Do I need to fireproof expansion joints?

Expansion gaps pass through buildings from basement to roof and in the event of fire can allow fire and toxic smoke to pass rapidly through the entire structure. Therefore, fire protecting expansion gaps is a critical element in protecting the users of a structure. This is particularly crucial where expansion gaps run through fire compartment walls and floors.

It must be understood that any fire protection element installed within expansion gaps MUST be able to move in response to predicted structural deflection and like the expansion joint itself, open and close in response to movement. Over the years we have seen installations where mineral fibre has been used to meet fire rating in critical zones. When the expansion gap has opened up a cavity opens between this mineral fibre allowing the passage of toxic smoke and fire.

We have developed a range of special fire protection products which will mirror the movement of the accompanying expansion joint.

- How do I choose the correct Joint system?

Movement joint systems are a specialised field and a different solution from the original envisaged often turns out to be the right choice. This can be for economic reasons but is often a technical nature. Sometimes it is impossible to use a particular joint because the use of the structure may mean that a more appropriate joint may have to be selected. For example, an expansion joint used in a school will not be suitable for use in a multi-storey car park. We therefore strongly recommend contacting our specialists for technical advice.

- How do I clean my joint systems?

Movement joint systems should be cleaned with a pH-neutral detergent. We have Operation & Maintenance (O&M) Manuals for all of our products but if you are in any doubt please contact our technical people for further advice.

- Is there a lot of maintenance required?

If preparation and installation instructions are followed closely, little maintenance will be required for jointing systems. By following the details set out in our installation Method Statements and O&M Manuals maintenance issues will be kept to a minimum. For specific joints, replacement parts are available in case of damage.